|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Prediction Software and Corrosion Modeling Software NAC-Compass®: Modeling and Prediction of High Temperature Naphthenic Acid Corrosion (NAC)

High-Value Software Solutions to Costly NAC Corrosion

Anytime Anywhere Any Device Any OS

No USB dongles No

installation No Browser Plug-ins

|

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|

|

Overview and Application Examples of NAC-Compass |

|

|

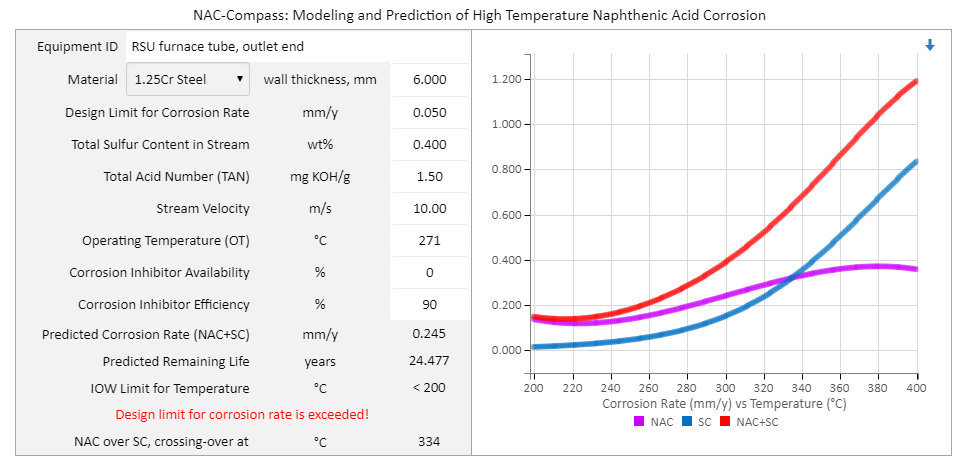

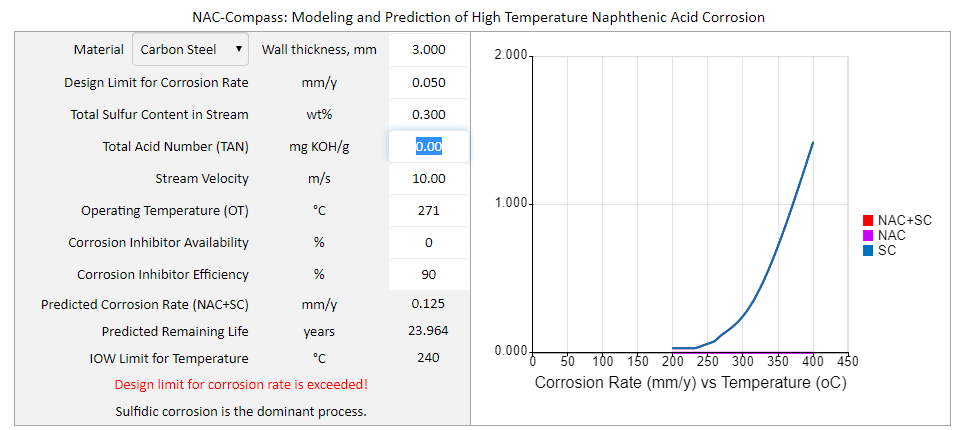

NAC-Compass is a cloud-based software that works on any device running any OS without the need for users to install or download anything. Figure 1 below shows an overview of the user interface of NAC-Compass.

Figure 1 NAC-Compass: software for predicting and modeling naphthenic acid corrosion (NAC). Note the capability of this software to quantify individual components of NAC and SC.

How to determine the integrity operating temperature limits for steels susceptible to naphthenic acid corrosion (NAC)?

Figure 2 NAC-Compass predicts high temperature naphthenic acid corrosion (NAC) and sulfidic corrosion.

Under the prevailing operating conditions shown in Figure 2 above, the corrosion rate of the selected 5Cr alloy steel is predicted to be 0.0.093 mm/y, above the design limit of 0.05 mm/y. The predicted remaining life of the equipment is 32 years. The predicted integrity operating window (IOW) limit for temperature for the selected alloy is 240°C. When the operating temperature is reduced to the IOW limit of 240°C predicted by NAC-Compass (Figure 3), the corrosion rate is reduced to a level within the design limit of 0.05 mm/y.

Figure 3 NAC-Compass predicts the integrity operating window based on the prevailing operating conditions.

How to select alloy steels for high temperature naphthenic acid corrosion resistance? How to determine the effect of corrosion inhibitors on naphthenic acid corrosion resistance and remaining life prediction? How to determine the effect of stream velocity on the high temperature naphthenic acid corrosion resistance of carbon steels, low alloy steels, and stainless alloys? How to determine the impact of sulfidic corrosion on naphthenic acid corrosion?

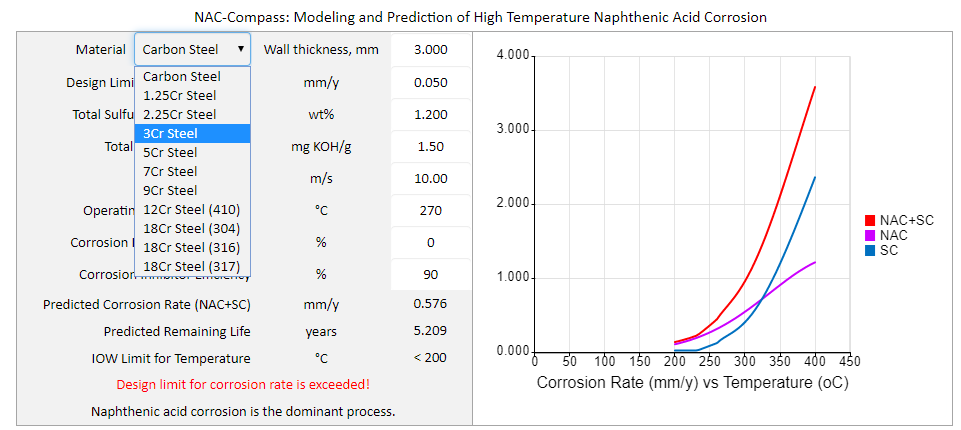

Under the prevailing operating conditions shown in Figure 1 above, 1.25Cr steel is not resistant to naphthenic acid corrosion. Another metallurgy must be evaluated and assessed. NAC-Compass is a powerful software tool for material selection for resistance to naphthenic acid corrosion (NAC). Users simply select the metallurgy from the dropdown list and the performance of the selected metallurgy is displayed instantly (Figure 4). NAC-Compass predicts that 18Cr (304) stainless steel is resistant to naphthenic acid corrosion under the prevailing operating conditions (Figure 5).

Figure 4 NAC-Compass: a software tool for material selection for naphthenic acid corrosion resistance

Figure 5 NAC-Compass: a software tool for material selection for naphthenic acid corrosion resistance.

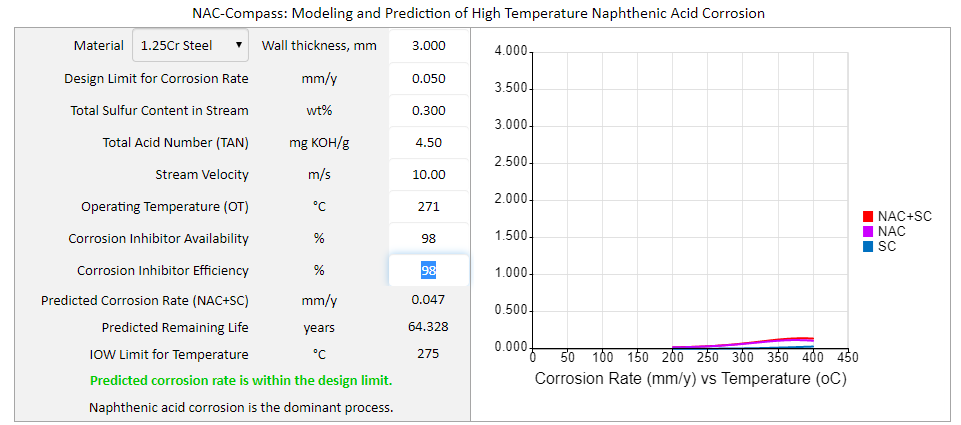

The other NAC mitigation measure is to use carbon steel/low alloys steels with corrosion inhibitors. The effect of corrosion inhibitors on naphthenic acid corrosion resistance and remaining life prediction can be rapidly evaluated using NAC-Compass software, as shown in Figure 6. An corrosion inhibitor at 90% inhibiting efficiency and 95% availability is not sufficient to reduce the corrosion rate to the design limit. However, if the corrosion inhibitor efficiency and availability are increased to 98%, the resulting naphthenic acid corrosion rate can be reduced to a level within the design limit of 0.05 mm/y (Figure 7).

Figure 6 NAC-Compass for evaluation and assessment of corrosion inhibitors for naphthenic acid corrosion resistance.

Figure 7 NAC-Compass for evaluation and assessment of corrosion inhibitors for naphthenic acid corrosion resistance.

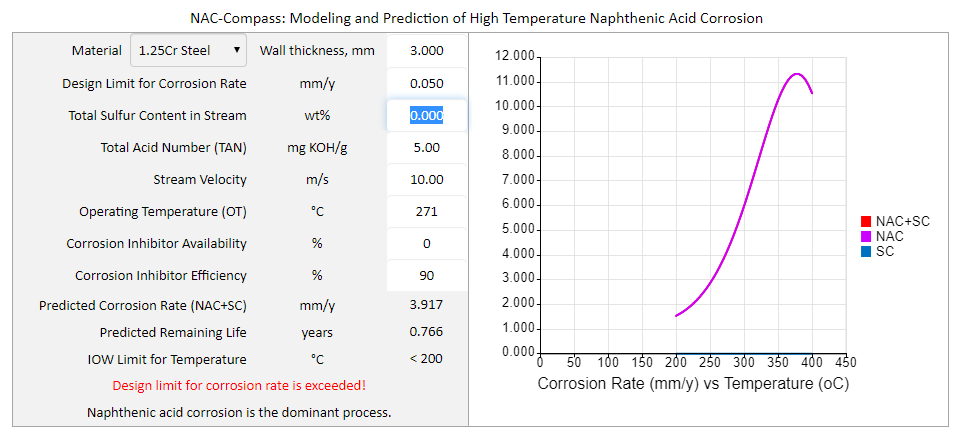

Sulfur content and total acid number (TAN) are two of the critical factors that affect naphthenic acid corrosion. At typical operating temperatures in oil refining, both sulfidic corrosion (sulfidation) and naphthenic corrosion are expected to take place at the same time in the equipment. NAC-Compass is capable of assessing the effect of each factor on the overall corrosion resistance of the selected metallurgy. NAC-Compass predicts the dominant corrosion process under the prevailing operating conditions. As shown in Figure 4 above, NAC-Compass predicts that naphthenic acid corrosion (NAC) is the dominant corrosion process below the temperature of 330oC and sulfidic corrosion (SC) will be the dominant process above 330oC. If the total sulfur content is set to zero (Figure 8), NAC-Compass models and predicts naphthenic acid corrosion only; if the total acid number (TAN) is set to zero, NAC-Compass models and predicts sulfidation (sulfidic) corrosion (Figure 9).

Figure 8 NAC-Compass software predicts the effect of sulfur on and its contribution to naphthenic acid corrosion.

Figure 9 NAC-Compass software predicts sulfidic corrosion and its contribution to naphthenic acid corrosion

The powerful applications of NAC-Compass are truly unlimited in engineering design, materials selection, process operation, inspection and maintenance, modeling and prediction of high temperature naphthenic acid corrosion.

Click here to contact us for licensing details and experience the power of NAC-Compass. |

|

NAC-Compass, giving you the right directions in the Modeling and Prediction of Naphthenic Acid Corrosion |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2025. All rights reserved. |

Naphthenic acid corrosion (NAC)

is a form of

high temperature corrosion that occurs primarily in crude and vacuum units, and downstream units that process certain fractions or cuts that contain naphthenic acids. Naphthenic acid corrosion is a function of the naphthenic acid content (total acid number, TAN), temperature, sulfur content, velocity and alloy composition. WebCorr's NAC-Compass is the only device and OS independent software tool on the market for the modeling and prediction of naphthenic acid corrosion. Designers, OEM engineers, consultants, operation personnel, maintenance and inspection engineers can quickly and accurately determine:

Naphthenic acid corrosion (NAC)

is a form of

high temperature corrosion that occurs primarily in crude and vacuum units, and downstream units that process certain fractions or cuts that contain naphthenic acids. Naphthenic acid corrosion is a function of the naphthenic acid content (total acid number, TAN), temperature, sulfur content, velocity and alloy composition. WebCorr's NAC-Compass is the only device and OS independent software tool on the market for the modeling and prediction of naphthenic acid corrosion. Designers, OEM engineers, consultants, operation personnel, maintenance and inspection engineers can quickly and accurately determine: